Megamp-Level High-Current Capability — ITECH Powers the Next Generation of Industrial Innovation

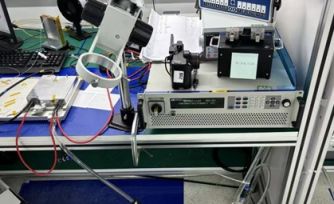

ITECH has recently and successfully delivered another mega-ampere-level high-current power supply system to a leading hydrogen energy manufacturer. The system, built around the IT-M3900D series high-power programmable DC power supplies, has now been officially commissioned on the customer’s next-generation electrolyzer production line.

This delivery imposed extremely high requirements on output capability, stability, and operational safety, and once again demonstrates ITECH’s engineering maturity and proven ability to deliver stable, reliable solutions for ultra-high-current applications.

01 High-Current Platform Designed for Cutting-Edge Industries

As renewable energy, electrochemical processes and advanced manufacturing continue to push toward higher power densities, more industries are moving toward megamp-level current requirements. The IT-M3900D Series high-power programmable DC power supplies, together with the IT-M3900C Series bidirectional programmable DC power supplies, are now widely deployed across multiple high-end sectors.

♦ Green hydrogen & electrolyzer production lines

♦ SOFC systems & superconducting equipment

♦ Electroplating, smelting & industrial electrochemistry

♦ High-power e-drive and power electronics

♦ Connector, fuse and terminal temperature-rise validation

Across all these applications, one requirement is universal: a stable, sustainable and engineering-grade high-current platform.

02 Core Engineering Challenges in High-Current Scenarios

Although use cases vary dramatically across industries, megamp-level systems consistently face similar engineering challenges:

♦ High-current density vs. system size & cost

Massive currents require heavier cabling and higher thermal overhead, making power density a central design target.

♦ Measurement accuracy affected by voltage drop

Long cable runs and thick conductors introduce voltage drops that compromise measurement precision.

♦ Long-duration reliability for 24/7 operation

Continuous 24/7 operation imposes strict requirements on system robustness and protection design.

♦ System controllability at megamp level

Parallel operation, current sharing, dynamic response and fault isolation become mission-critical.

These challenges mean high-current systems must not only deliver power, but sustain and stabilize it over long operational cycles.

03 IT-M3900D / IT-M3900C: A Proven Solution for Engineering-Grade High-Current Applications

The IT-M3900D high-power DC supplies and IT-M3900C bidirectional DC supplies provide a stable foundation for megamp-level applications.

♦ High power density for compact system design

1U/6 kW and 2U/12 kW units deliver significant current in a compact footprint, reducing facility and distribution overhead.

♦ Modular scalability from 100 A to 10,000 A+

Flexible parallel operation supports a unified platform from R&D to mass production, reducing lifecycle maintenance cost.

♦ High accuracy & low ripple with line-drop compensation

Ensures stable and repeatable output performance for precision-critical applications.

♦ Seven-layer protection for long-duration stability

OVP / OCP / OPP / UCP / UVP / OTP / Reverse

SENSE

A multi-layer protection chain ensures safe, continuous operation at extremely

high currents.

♦ Bidirectional energy capability (IT-M3900C)

Supports discharge, energy regeneration and pulse absorption—essential for e-drive, storage and electrochemical applications.

The successful delivery of this mega-ampere-level system to a leading hydrogen energy manufacturer once again demonstrates the engineering maturity of the IT-M3900D series high-power programmable DC power supplies and the IT-M3900C series bidirectional programmable DC power supplies in high-current applications.

Looking ahead, ITECH will continue delivering higher power

density, stronger platform scalability and more robust system architectures to

support the industries shaping the future of high-power and high-efficiency

innovation.