The Application of ITECH IT6000C Power Supply in the Fiber Laser Industry

With the widespread application of semiconductor lasers in fields such as industrial processing, medical equipment, and optical fiber communications, the performance testing requirements for their core component—the fiber laser—have become increasingly demanding. Fiber lasers, known for their lightweight design, high power output, and excellent stability, offer distinct advantages over semiconductor and solid-state lasers.

They are widely used in defense, military, medical, and industrial sectors. As the core driving unit of fiber lasers, the quality of power supplied to the pump source directly affects the laser’s output stability, photoelectric conversion efficiency, and overall lifespan. The ITECH IT6000C Series high-precision programmable DC power supply, with its unique performance advantages and flexible function expansion capabilities, has become an ideal solution for testing in the semiconductor laser industry.

Application Advantages of the IT6000C:

In the development of fiber lasers, the maximum power test of the pump source is a critical step in verifying the performance limits of the laser. The IT6000C series power supply supports up to 18kW per single module, and power can be expanded up to 2MW through parallel connection. It offers output voltages up to 2250V and currents up to 2040A, easily meeting the testing requirements of high-power semiconductor lasers.

Semiconductor lasers are highly sensitive to current and extremely vulnerable to transient overshoot from the power supply. The IT6000C series features a CC/CV priority mode. When testing current-driven devices, the internal mode can be set to CC priority, effectively protecting laser diodes from damage caused by inrush current or overshoot.

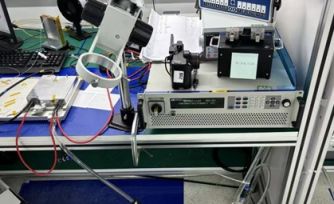

In traditional testing setups, users often need to operate multiple devices simultaneously—such as power supplies, power meters, and oscilloscopes—leading to system complexity and poor data synchronization. The IT6000C series power supply, with its high measurement and setting accuracy (voltage: 0.02% + 0.02%FS; current: 0.1% + 0.1%FS), can replace the functionality of multiple instruments.

For example, in fiber laser electro-optical conversion efficiency testing, users only need to externally connect a thermal power meter to measure the laser output power. Input power parameters—including voltage, current, and power—can be directly read from the power supply’s built-in high-precision digital meters. With a simple calculation, the conversion efficiency can be obtained. This high-precision solution not only reduces equipment costs but also avoids errors from multi-instrument calibration, significantly improving the reliability and consistency of test data.

The IT6000C series power supply also offers a wide range of digital interfaces on the rear panel (LAN/USB/GPIB) along with I/O terminals, enabling fast response to external signals and synchronized control with multiple devices—demonstrating strong adaptability to diverse application scenarios.

Precision Testing Case:

Case 1: Rapid Emergency Stop Protection

During high-power pump source testing, a customer experienced multiple "fiber explosions" due to defects at the fiber splicing point, posing a fire hazard. Traditional solutions required either modifying the test system or adding complex external protection circuits. However, with the IT6000C, this issue was resolved simply by connecting a switch between the IO5 terminal and IO GND on the power supply’s rear panel to control the power ON/OFF. Combined with internal trigger settings, the system enabled a “rapid output cutoff” function.

In the event of fiber failure, the operator can immediately shut off the power output, greatly reducing the risk of human error during emergency handling and significantly enhancing test safety.

Case 2: Synchronized Control of Dual Pump Sources

To meet the testing requirements of dual-pump fiber lasers, the IT6000C enables

synchronized current/voltage output across multiple units by linking with IO

trigger signals. For example, when testing dual-pump lasers, two power supplies

can be controlled simultaneously—turning on/off in sync—through the operation

of just one unit. This ensures consistency in pump source output and simplifies

system coordination.

Looking ahead, fiber lasers will continue to evolve toward full fiberization and integration, with increasingly compact form factors. ITECH’s power supplies, with their high-precision output, flexible waveform programming, intelligent interface expansion, and comprehensive protection mechanisms, provide efficient and safe testing solutions for the semiconductor laser industry. As laser technology advances, ITECH will continue to drive testing innovation with cutting-edge solutions that empower the next generation of laser development.