High Power/High Current Fuel Cell EIS Test Challenges and Solutions

1. Background: International Trends in Fuel Cell Testing With the global focus on sustainable energy, fuel cell technology is being increasingly applied in transportation, stationary power systems, and portable devices. To ensure the performance and longevity of fuel cells, precise testing and diagnostic methods have become critically important. Internationally, research institutions and enterprises are dedicating resources to the development of advanced testing platforms that address various performance evaluation needs—from laboratory research to high-power application scenarios.

In the study of high-current water electrolysis, researchers also aim to understand the dynamic processes of water molecule decomposition under high-current conditions. This is essential for optimizing the efficiency and stability of electrolysis systems and accelerating the transition from laboratory research to real-world applications.

2. Principle of Electrochemical Impedance Spectroscopy (EIS)

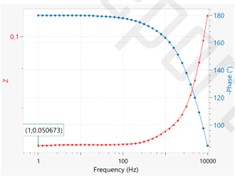

Electrochemical Impedance Spectroscopy (EIS) is a technique that involves applying a small-amplitude AC signal to an electrochemical system and measuring its response over a range of frequencies. EIS provides valuable insights into processes such as charge transfer, electrode interface reactions, and mass transport within the system. By analyzing Nyquist and Bode plots, researchers can construct equivalent circuit models to gain a deeper understanding of the underlying mechanisms of electrochemical processes.

3. Challenges of High-Current EIS Testing

In high-power fuel cell

systems, conducting EIS tests presents several challenges:

- Signal Stability: Under high-current conditions, increased system noise and interference can compromise measurement accuracy.

- Frequency Response Capability: Traditional testing equipment may not cover the required frequency range, limiting the analysis of the system’s dynamic behavior.

- System Integration: Integrating EIS testing into existing high-power test platforms requires careful consideration of equipment compatibility and operational safety.

4. Solution: High-Power Expansion of the Electrochemical

Workstation Platform

To address the challenges

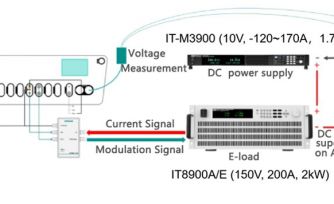

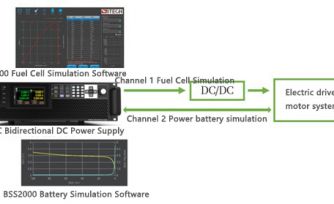

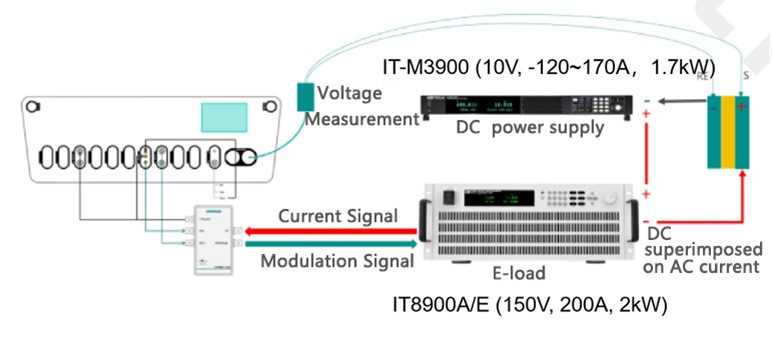

mentioned above, customers combine EIS testing equipment with ITECH’s

high-performance electronic load IT8900A/E and bidirectional DC power supply

IT-M3900C to perform EIS tests on high-power fuel cell systems. This platform

offers the following features:

- High Current Handling Capability: Enables constant current charging or discharging under high-current conditions, with the maximum current determined by the specific DC power supply and electronic load models used.

- Wide Frequency Response Range: Covers a broad frequency range from 1 Hz to 10 kHz, providing comprehensive insights into the system’s dynamic behavior.

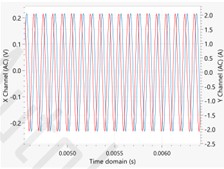

- Stability and High Accuracy: FFT analysis of the AC signal and EIS measurement results demonstrate stable and precise current control, ensuring high reliability and repeatability of experimental data.

AC test results and 10kHz AC voltage and current signal

5. Key Equipment Features

In this testing platform, the selection of the electronic load and DC power

supply is crucial. Below are the key features of two essential devices:

1. IT8900A/E High-Speed High-Power DC Electronic Load

- High-Speed Dynamic Response: Supports dynamic operation up to 30 kHz, ideal for transient response testing of switching power supplies.

- Multiple Operating Modes: Offers CC, CV, CR, CP modes to meet a variety of testing requirements.

- Low-Voltage Load Capability: Capable of handling high current at low voltages, making it suitable for testing low-voltage, high-current devices such as fuel cells.

- Rich Communication Interfaces: Equipped with built-in CAN, LAN, GPIB, USB, RS232, and analog interfaces for easy system integration.

2. IT-M3900C Bidirectional Programmable DC Power Supply

- Bidirectional Current Capability: Capable of both sourcing and sinking power, allowing fast switching between power supply and load modes.

- Wide Output Range: Offers output voltages from 10 V to 1500 V, with single-cabinet current up to 1020 A, accommodating a wide range of testing needs.

- High-Efficiency Energy Regeneration: Includes energy feedback functionality, improving energy efficiency and reducing testing costs.

- Built-in Function Generator: Supports arbitrary waveform generation for complex testing scenarios.

6. Conclusion

As fuel cell technology continues to advance rapidly, precise and efficient

testing methods are essential for accelerating its commercialization. By

utilizing an EIS testing platform powered by ITECH’s DC power supplies and

electronic loads, researchers can conduct high-current EIS tests on systems

such as Solid Oxide Fuel Cells (SOFCs) and Proton Exchange Membrane Fuel Cells

(PEMFCs). In addition, this platform supports in-depth research into

high-current water electrolysis—enabling the optimization of electrodes,

catalysts, or electrolyzer diagnostics. It can also be used during mass

production to establish impedance baselines, enhancing the overall efficiency

and stability of electrolysis systems.