Multiple battery companies open high-capacity cell race, energy storage cell testing ushered in new challenges

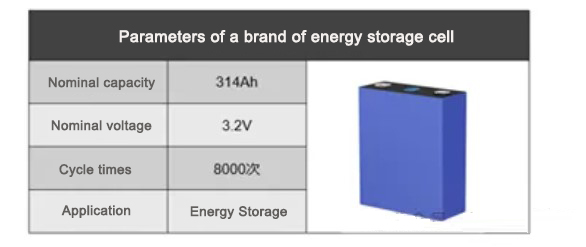

Under the pressure of cost reduction and efficiency, batteries and system integrators have flocked to larger capacity cells and higher capacity energy storage system tracks. According to different capacities, energy storage cells can be divided into three generations of products, the first generation of 280Ah, the second generation of 300Ah or more energy storage cells, represented by 314Ah capacity.

Energy Storage Cell Hours Competition

At present, the competition of 300Ah+ energy storage core and 5MWh energy storage system has entered a white-hot stage. According to the incomplete statistics of Energy Storage Network, since 2023, more than 40 companies have successively launched 20 sizes of 300Ah+ large-capacity energy storage special batteries/5MWh+ energy storage systems.

At the same time, this year, a number of battery manufacturers have intensively released the third generation of energy storage cells with a capacity of 500 Ah or more, and 500+Ah, 600+Ah, 700+Ah and even 1000+Ah high-capacity cells have appeared on the market. This also indicates that the R&D and testing of high-capacity battery cell products will bring new challenges.

New Challenges in Testing Large Capacity Energy Storage Cells

1. Battery capacity is getting bigger and bigger, charging and discharging current is getting higher and higher

GB36276- 2023 “lithium-ion batteries for electric energy storage” standard, the requirements of the battery monomer and battery module can be charged and discharged under the conditions of 4P, and the energy efficiency is not less than 88%.

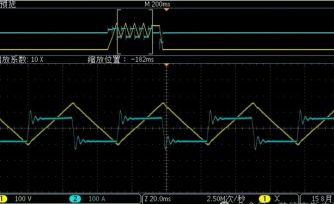

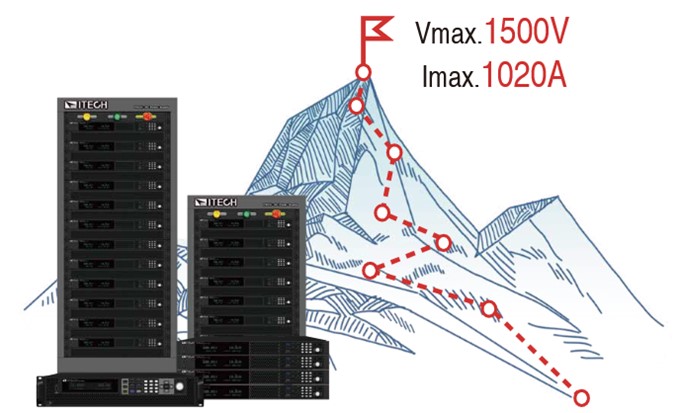

Taking the common 314Ah Li-ion energy storage battery as an example, charging and discharging test with a multiplication rate of 4P, the charging and discharging current is definitely greater than 1000A. Therefore, in order to meet the current test range of the energy storage battery cell, it is often necessary to configure higher power charging and discharging equipment.

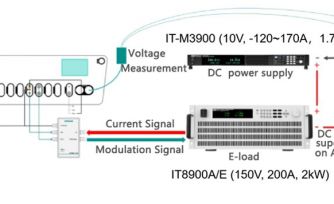

ITECH IT-M3900C series bi-directional DC power supply, with low-voltage and high-current models, the maximum output current of a single machine can be up to 1020 A, and the master-slave parallel current can be up to 10,000 A. It supports seamless switching of bi-directional currents, and a machine can be used for both charging and discharging tests.

2、The cycle times of energy storage battery cells are higher than those of ordinary batteries, and the test cycle is longer.

The national standard “lithium-ion battery industry norms and conditions” to its energy storage battery single battery cycle life ≥ 6000 times and capacity retention rate ≥ 80, battery pack cycle life ≥ 5000 times and capacity retention rate ≥ 80%. And the actual major manufacturers of energy storage battery cell cycle times are much greater than this value.

Cycle life is a mandatory test item for battery products, which means that energy storage cells need to be tested for a longer period of time. Therefore, a highly automated and stable product is needed for cycle life testing to reduce the workload of R&D and testing personnel.

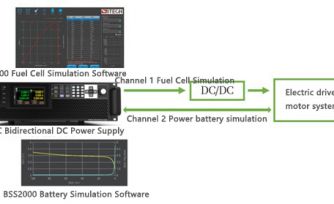

ITS5300 Battery Charge and Discharge Test System

ITS5300 Battery Charge and Discharge Test System provides professional test steps to help users significantly improve test efficiency. The modular design allows users to select the appropriate instrument for their own testing needs to build an automated test platform. The system is equipped with a variety of sound and light emergency stop protection devices to provide a full range of protection for battery charging and discharging, to ensure long-term stable operation of the system. Supporting power failure memory saving, the system can still save the data after power failure and other abnormalities, and after the system is restored, the previous test can be continued, avoiding the trouble of repeated testing and improving the efficiency of testing.

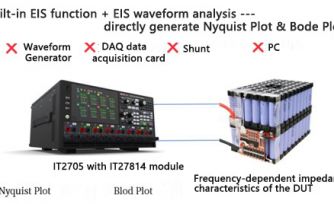

ITECH provides professional battery testing solutions for all kinds of batteries (Li-ion NiMH, supercapacitor, fuel cells, solid state batteries, liquid batteries, etc.), as well as cells, packs, modules and other different stages of resistance and capacitance testing. Click “Read More” to learn about ITECH Battery Testing Solutions.