Test solution for forced battery discharge

Lithium batteries applications

As an efficient and convenient energy storage method, lithium batteries have penetrated into every corner of our lives. Among portable electronic devices, mobile phones, tablets, laptops, and even digital cameras are inseparable from the support of lithium batteries. Drones, robots, smart homes, etc. are also need the support of lithium batteries.

Lithium batteries also play an important role in the field of electric vehicles. Nowadays, more and more electric vehicles use lithium batteries as their power source, and their high energy density and environmentally friendly nature make electric vehicles have longer range and lower emissions.

Energy storage system is also an important application field of lithium batteries. Energy storage systems in household, industry, power grid and other fields utilize lithium batteries to store excess power so as to release the energy and balance the energy supply at the peak of energy demand. The capacity of power and energy storage batteries is larger, and the requirements for safety performance are also higher.

Lithium battery standards have been updated, did you know?

The latest version of IEC62133 standard splits lithium batteries and nickel batteries into 2 standards, i.e. IEC62133-1:2017 corresponding to nickel batteries. Among them, IEC62133-2:2017 lithium standard has been updated for battery pretreatment, external short circuit test, thermal shock test, extrusion test, overshoot test, forced discharge test, etc. Take battery forced discharge test as an example:

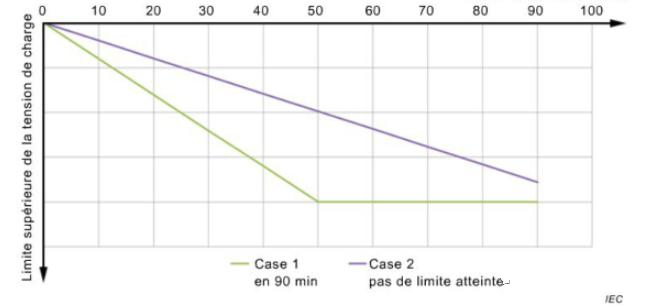

The discharged cell is reverse charged with 1C current to the negative of the upper limit charging voltage for 90 minutes.

Fig. 1 Reference curve for IEC62133-2:2017 forced discharge test

How to solve the battery forced discharge test?

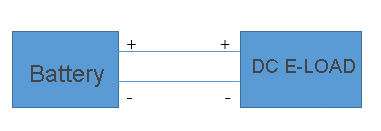

The batteries mentioned in the specification requirements are continuously discharged after 0V, i.e. negative voltage discharge. It is difficult to do this with electronic loads in general.

Figure 2 Normal Battery Discharge Test Method

Since the transistor Vce will not work in the state of 0V, the electronic load devices are specified with a minimum operating voltage (Fig. 2). As in the example in Fig. 1 above, the battery is discharged in the state of negative voltage, and the electronic load will report an error, and the test can not be continued.

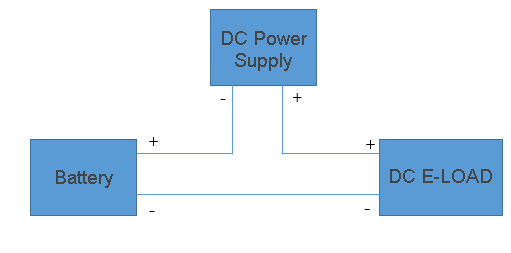

ITECH has successfully solved this problem by adding a bias power supply to the experimental circuit.

Figure 3 Battery forced discharge test method

As shown in Figure 3, this power supply acts as a bias power supply to ensure that Vce has sufficient voltage even if the battery is in a negative voltage state, thus ensuring that the electronic load can operate within the rated voltage range. During the test, if the battery voltage drops to the negative value of the upper limit of the battery charging voltage, the battery voltage should be maintained stably near the negative value of the upper limit of the voltage until the end of the test; if the battery voltage fails to reach the negative value of the upper limit of the battery charging voltage, the test will continue until the end.

By doing the above, the tests in the IEC62133-2:2017 standard for forced discharge are completed.

Compulsory discharge test is also required by different test standards such as UN38.3, CQC certification, etc. ITECH DC power supplies, DC electronic loads, bi-directional DC power supplies, battery test systems and other products can complete all kinds of battery electrical safety tests and working condition simulation tests.