IT8500G+ electronic load automatic test function, a good helper for cost reduction and efficiency increase

How to reduce costs and increase efficiency for your testing?

Product testing is very important in the product development process and before delivery. The efficiency of testing will affect the development progress and delivery cycle. Therefore, the importance of improving product testing efficiency is self-evident.

For example, in the test of DC power supply, the traditional test is usually through manual operation and manual judgment. The test process is to manually set the parameters of the DC electronic load for load testing, manually record the output parameters of the power supply under different load conditions, and then the operator judges whether the power supply is qualified according to the standard.

However, there are some disadvantages in the traditional way of power supply testing. First of all, it takes a lot of time and human resources because it needs to manually set up and analyze the test results every time; second, due to the low proficiency of the operator and some subjective factors, the test results may be biased; finally, in the product When the number and test items are relatively large, traditional manual testing will appear to be more inefficient.

In order to cope with large-scale high-frequency testing and improve testing efficiency, ITECH has launched IT8500G+ series programmable DC electronic load with automatic testing functions.

IT8500G+ Programmable DC Electronic Load

IT8500G+ high-performance programmable DC electronic load has both desktop and system integration dual-use requirements. It is specially designed for research and development and burn-in testing of mobile power supplies, industrial power modules, power electronic devices and fast charging adapters. It not only has the traditional CC/CV/CR/CP load mode, but also provides composite load modes such as CR+CC/CV+CC/CR-LED, so as to be widely applicable to different characteristics of the DUT. Excellent performance in overshoot and dynamic loading.

IT8500G+ series DC electronic load has automatic test editing mode. Autotest can program, test and display whether the test passed or failed for a device, which is very useful for users. The automatic test operation only needs to include four steps: edit, save, recall and run.

The test operation is simple, and the keys can be completely locked (press (Shift)+(Lock)) to prevent accidental touches on the keyboard from affecting the normal test. The electronic load will automatically detect the change of the input voltage to judge whether to start the test, turn on the automatic test start function (AUTO-RUN), when the object to be tested is connected, the load detects that the input terminal voltage rises from 0 to the set start voltage (TRIG-VOLT), the automatic test starts running without resorting to an external trigger source or manually providing a trigger signal.

An automatic test file can contain up to 50 steps, set the load mode (CC, CV, CW, CR) of each step and whether to short circuit, and then set the type of measured value (voltage, current, power) and the upper limit of the judgment value Lower limit, and then set the delay time, that is, how long does it take to read the test value after the input is set, to wait for the output to stabilize before testing, the delay range is 0.1~30 seconds, and finally save it, an automatic test is edited up. Compared with IT8500 and IT8500+ series DC electronic loads, IT8500G+, as an upgraded version, can edit more steps and add a new fast charging protocol to choose, and the realization of functions is simpler and easier to understand.

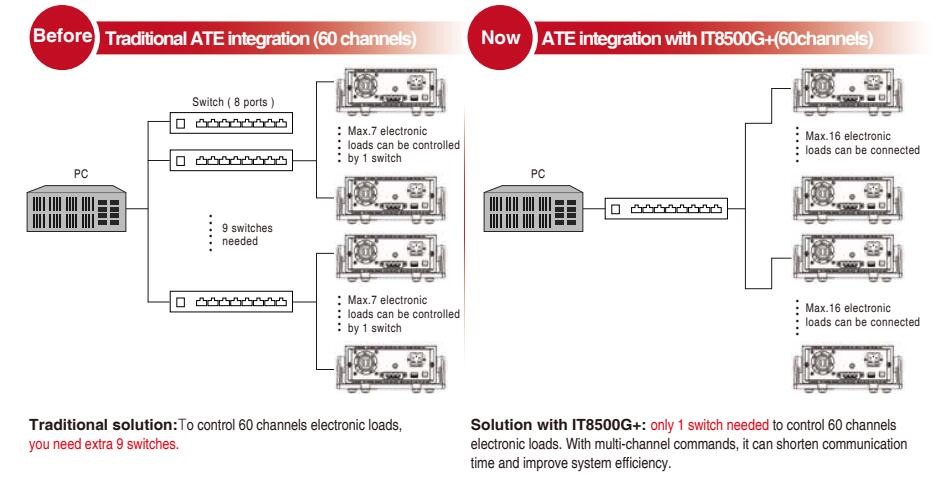

Not only that, relying on the unique multi-channel mode and built-in ripple measurement function of the IT8500G+ electronic load, it can easily realize program control of hundreds of channels without additional oscilloscopes and too many communication interface cards, reducing test costs and improving test efficiency for enterprises.

In the traditional ATE integration scheme, if each electronic load uses the Ethernet communication interface for independent communication, multiple switches need to be configured in the system, which not only increases the equipment cost but also increases the failure probability of the system. IT8500G+ series has a professional multi-channel mode, which can cascade up to 16 devices. The ATE system only needs to communicate with one interface to control 16 electronic loads. Through commands, 16 cascaded IT85G+ loads can be operated synchronously, and the operating data can also be sent or collected for the specified channel to achieve an asynchronous operation effect, and the configuration and use are very flexible.

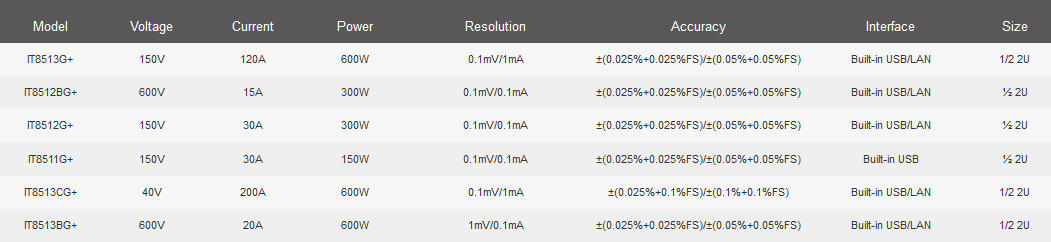

In addition, IT8500G+ series electronic loads also provide eight fast charging communication protocols: QC2.0, QC3.0, PE+, PE2.0+, USB PD2.0, USB PD3.0, FCP, and SCP; with OPP/OCP Test function, suitable for power module protection function test; battery discharge mode, providing three cut-off conditions of time, voltage and capacity; test resolution can reach 0.1mV/0.1mA, etc.

In R&D and aging tests of mobile power supplies, industrial power modules, power electronic devices and fast charging adapters, IT8500G+ series DC electronic loads will be a good helper to reduce test costs and improve test efficiency.