Forced discharge test of battery

Background Effective January 1, 2009, the latest version of the Technical Instructions for the Safe Transport of Dangerous Goods by Air issued by the International Civil Aviation Organization (ICAO) added UN serial numbers for dangerous goods, and lithium batteries will be classified as lithium-ion batteries (UN 3090 and UN 3091) and lithium metal batteries (UN 3480 and UN 3481). The regulation states that lithium batteries cannot be transported by air if they do not come with a test report or certificate of approval based on UN38.3.

UN 38.3 – Lithium metal and lithium-ion batteries is a subsection of the UN Manual of Tests and Criteria Part III that focuses on the requirements regarding lithium metal batteries and lithium-ion batteries. UN38.3 refers to Part 3, paragraph 38.3 of the United Nations Manual of Tests and Criteria for the Transport of Dangerous Goods, which requires lithium batteries to pass height simulation, high and low temperature cycling, vibration test, shock test, external short circuit at 55°C, impact test, overcharge test, and forced discharge test before transportation to ensure the safety of lithium batteries.

Forced discharge means that the battery discharges the internal stored power. When the voltage reaches a certain value, continued discharge will cause over-discharge. It will destroy the crystalline structure of the positive and negative electrodes of the battery, making the thermal stability of the two electrodes become poor, and the negative electrode produces a large amount of hydrogen gas, which catalyzes the decomposition of the organic electrolyte. When the temperature is high enough, the positive electrode will decompose and produce a large amount of hydrocarbons, which will eventually lead to the rupture and fire of the battery.

Case study

The purpose of this test is to evaluate the ability of the battery cell to withstand forced discharge.

Test method:

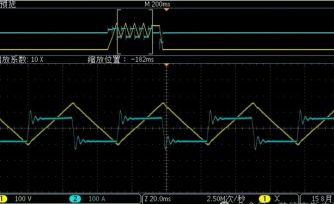

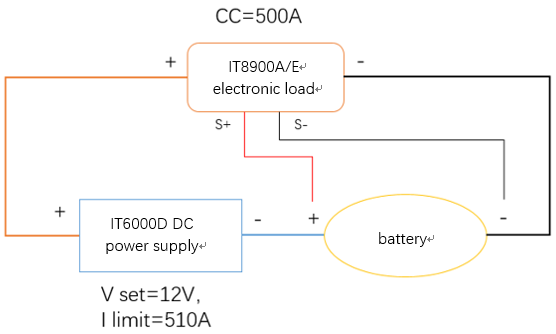

Connect the battery sample in series with a 12V DC power supply and start discharging at the maximum discharge current. The time is equal to the rated capacity divided by the initial current. We’ll see whether the battery will rupture or catch fire as described above.

A customer's real case:

It requires 500A to do forced discharge on the battery.

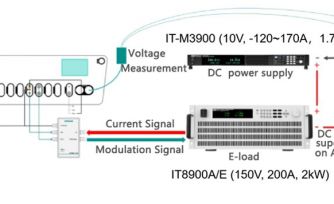

They use a unit of ITECH IT6030D-80-900 high power DC power supply (set it as 12V/510A) in series with the battery (single 3.7V). Then they use an IT8912A-150-1200 high performance DC electronic load( set CC=500A ) to discharge it. Turn on the sense function of the load, through the remote measurement terminal, the voltage of the battery can be read back in real time. And they record the voltage and current data used for this experiment through the supporting software. Finally they analyze and draw conclusions after the test.

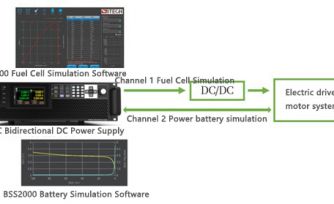

Bidirectional DC power supply

ITS5300 battery charge and discharge test system.