How to use IT2800 Graphical Source Measure Unit to conduct a magnetic resistance test?

Background In electromagnetism, when the current passes through the conductor perpendicular to the direction of the external magnetic field, there is a potential difference between the two sides of the conductor perpendicular to the magnetic field and current direction.

Case study

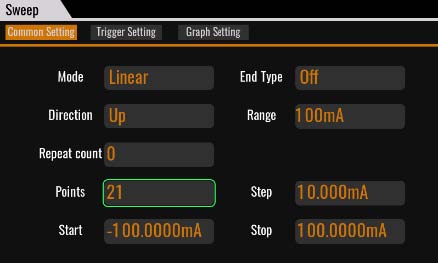

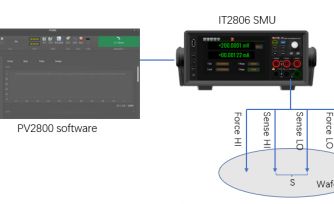

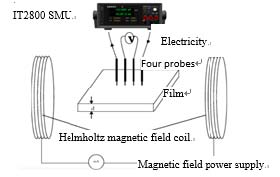

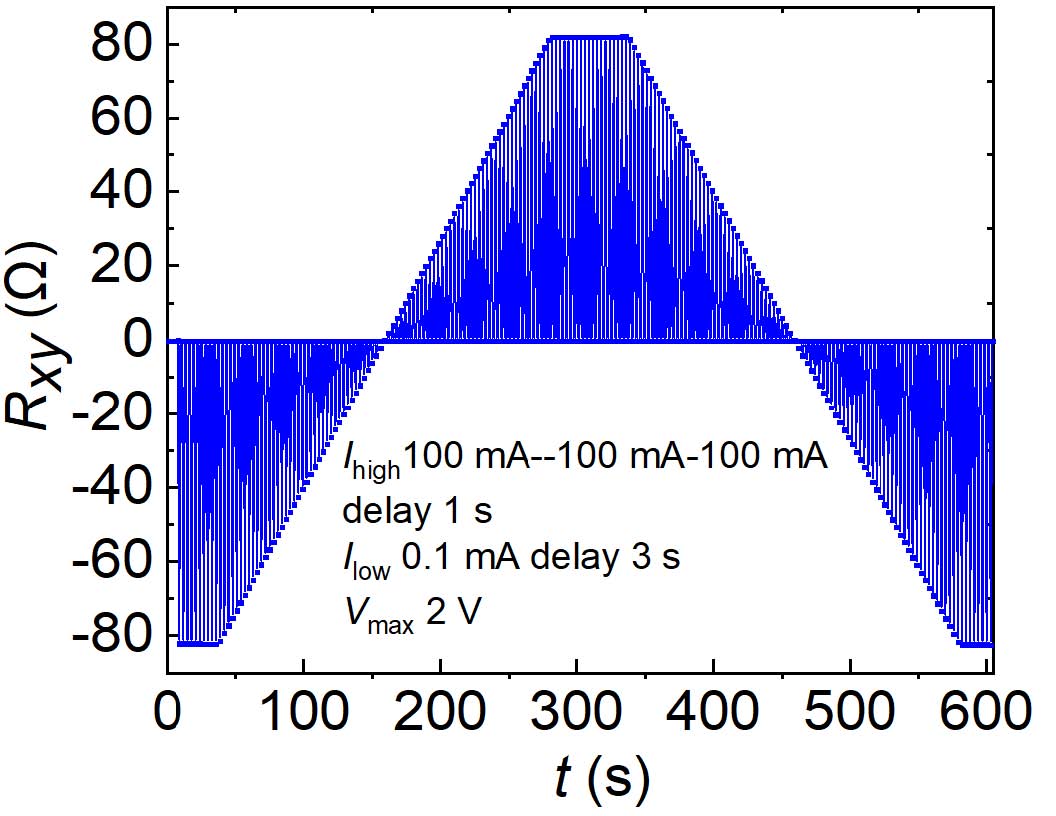

An ITECH user in the material field needs to conduct resistivity test of thin film magnetic resistance. In this test, it is required to build a changing magnetic field and input high-accuracy constant current source to the magnetic resistance under test, then test the magnetic resistance and magnetoelectric properties of the film magnetic resistance through the four probe method. The constant current source needs to be output at a constant current of 1mA, and the resolution is 1nA. In addition, a pulse scanning function is required to scan the high level from 100mA to -100mA and scan the low level to 0.1mA. Therefore, the power supply with a constant current source is required to have high resolution and accuracy to ensure accurate and stable tests as well as continuous and stable scanning function from positive current to negative current. The user selects the IT2800 Graphical Source Measure Unit to complete this test. The test principle is as shown in the figure below.

Built in with a standard SWEEP mode, IT2800 supports linear and logarithmic, single and dual up and down scanning function, as well as constant and pulse scanning function. The LIST scanning function can effectively execute any waveform output, which is extremely helpful in tests when the characterization response changes with the voltage or current change. You can generate a scanning curve of any shape through excel import or panel editing. Up to 99999 points of data can be imported, making this device an ideal choice for UI characteristic curve test. In the test, SWEEP can be used to complete all scanning for the positive and negative voltage and positive and negative current tests without changing wiring. You can observe the actual output curve on the Scope interface.