Do you know the technical principle in the thermometer?

With the recent outbreak of influenza A, all kinds of thermometers have once again become an essential item for home health monitoring. The core component of the electronic thermometer commonly used at present is the temperature sensor. The working principle of the thermal sensor is to use the radiant heat effect to cause the temperature of the detection device to rise after receiving radiant energy, thereby changing the performance of the column and temperature in the sensor. By detecting a change in one of these properties, radiation can be detected. In most cases, when the device receives radiation, it causes a non-electrical physical change, and then changes it into electric quantity through appropriate changes for measurement.

Temperature sensor characteristics:

Small size: reduce the space occupied by the internal circuit and make the product more portable;

Low power consumption: the power-down mode current is only 1.1uA, which means that the battery consumes very little power when the thermometer is not working. This parameter is very important for battery-powered products;

High accuracy: The higher the accuracy of the sensor, the more accurate the measurement.

Questions: What is advantages of ITECH Test Solutions?

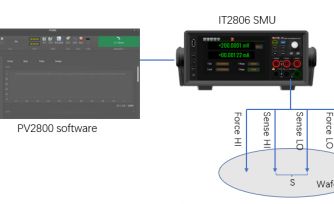

ITECH has always been committed to providing a full range of test and measurement solutions for the power electronics industry. The newly launched IT2800 series of high-precision source measurement units can complete all tests with one device.

1. Power consumption current test

Compared with the traditional test solution, While using a high-precision power supply to provide voltage, it needs to be measured with another independent ammeter, which not only costs a lot but also occupies limited test bench space. The IT2800 series source measurement units SMU provides engineers with an economical and efficient solution. It integrates six device functions, integrates different output and measurement capabilities into a compact 2U half rack, and can accurately output voltage or current and simultaneously measure voltage and/or current. It combines the functions of the following instruments: 4-quadrant voltage source, current source, 6 1/2 digital multimeter, pulse generator, battery simulator, and electronic load. And the resolution can reach up to 10fA/100nV, the sampling rate can reach up to 10us, which can complete the low power consumption test efficiently and conveniently.

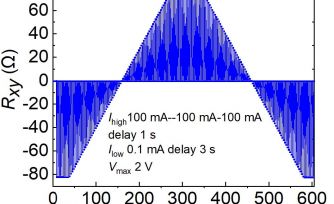

2. Sensor temperature rise test

In order to better understand the temperature rise characteristics of the sensor, the Recorder function provided by IT2800 allows users to view historical waveforms and table data within a period of time. The minimum sampling interval is 100us, and a maximum of 1 million points of data can be recorded. It also supports exporting to a spreadsheet (.CSV) for further analysis, greatly improving the efficiency of test debugging and debugging, and easily recording sensor characteristic curves.

The IT2800 Series are compact and cost-effective bench-top Source Measure Units (SMUs) with the capability to source and measure both voltage and current. The IT2800 Series combine the capabilities of a voltage source, a current source, a voltage meter, a current meter and an ohmmeter (along with the capability to switch easily between these various functions).This ensures the independent measurement of IV characteristic in 4-quadrant. With a current range of 10fA to 10A and a voltage range of100nV to 1000V, the IT2800 series SMU has capabilities that allow it to perform more than just simple DC and pulsed measurements to prevent errors inmeasurement results due to the device's own heating. Excellent Front Panel GUI with 5 inch touch display supports various view modes, to help engineers significantly improve the efficiency of testing. The IT2800 Series source measurement units SMU is suitable for a variety of test applications: discrete semiconductor devices, passive devices, transient suppression devices, laser diodes, TVS, varistors, etc.