ITECH provides solutions for heat resistance testing of new energy vehicle wiring harness

What is a car wiring harness? Car wiring harness, like the nerves and blood vessels of a car, carries the transmission of car power and signals, and is an important part of car parts. The automotive wiring harness is mainly composed of three parts, namely cables, wrapping materials and connectors (terminals).

Automotive wiring harnesses can be divided into high-voltage wiring harnesses and low-voltage wiring harnesses according to voltage. The voltage of high-voltage wiring harnesses is 300V and above, which is mainly used for driving power transmission of new energy vehicles; The voltage of the low-voltage wiring harness is below 60V, and the general vehicle voltage is 12V, which is mainly used for the transmission of vehicle signals. Automotive wiring harnesses can be divided into engine wiring harnesses, instrument wiring harnesses, lighting wiring harnesses, air conditioning wiring harnesses, and auxiliary electrical wiring harnesses according to their composition.

Characteristic requirements for automotive wiring harnesses

In addition to the performance requirements of the automotive wiring harness, due to its complex working and operating environment, for example, the engine wiring harness needs to withstand the high temperature and vibration environment of the engine compartment; the door wiring harness needs to have enough bending times to ensure the normal operation of the door components. Different environments require wiring harnesses to have different characteristics, which can be summarized into the following four types of characteristics:

Heat resistance: According to the working environment temperature of the wiring harness wires, wires with different temperature resistance grades are selected. The wires in the passenger compartment can be selected with a temperature resistance rating of 90°C; the engine compartment wiring harness can be selected with a temperature resistance rating of 180°C; the wires crossing the above two areas should be selected with a temperature resistance rating that meets the temperature requirements of the two areas wire.

Abrasion resistance: The wire itself should have the ability to prevent the damage and leakage of the insulator caused by the wear of the wiring part. When designing, the wires should try to avoid contact with parts that are prone to vibration to prevent wear and tear of the wire harness. If unavoidable, wrapping tape or additional bellows can be used.

Flame retardancy: Flame retardancy refers to the requirement that the burning time and range of parts be controlled within a certain range after being caught on fire.

Bending: The repeated bending of parts that require bending. The degree of bending of the parts, the number of allowable bending times, and the ambient temperature should be set according to the usage conditions. For example, the rubber sleeve used for the car door is required to reach 180°/100,000 times/-30~80°C.

As a professional manufacturer of power electronics testing instruments and systems, ITECH provide comprehensive testing solutions for heat resistance testing of automotive wiring harnesses.

ITECH Cases

Cases 1.

Test requirements: A customer tests the temperature change of the wire harness by increasing the current to the wire harness under test.

Test equipment: The customer chooses ITECH programmable DC power supply IT6015D-80-450 as the power supply. Later, due to the upgrade of the client product, the test demand current index is upgraded to more than 600A. After paralleling two products of the same model, the test index can be achieved.

Cases 2.

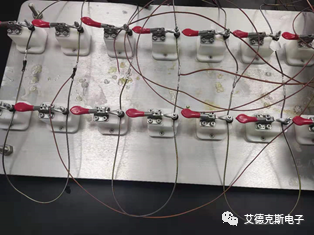

Test requirements: In the temperature rise test, a customer installs the connector to be tested in the test equipment, passes a current of more than 1000A, repeatedly increases or decreases the input current, observes the change of the output current and temperature value, and judges the connector Whether it can be applied to new energy vehicles.

Test equipment: The customer chose ITECH bidirectional programmable DC power supply IT6045C-80-1350 to complete the temperature rise test. This type has a maximum current of 1350A, fully covering the customer's test, and has a fast dynamic response time, panel LIST editing, and the function of extending the current power of the master-slave parallel machine. If users have higher current upgrade test requirements in the later stage, ITECH products can also perfectly cover them.

Cases 3.

Test requirements: A customer is engaged in automotive electronics connectors, and the stability of the wiring harness needs to be verified during the production process.

Test equipment: ITECH programmable DC power supply IT6534C and high-power programmable electronic load IT8902E are used to complete the temperature rise test of the wiring harness, and the temperature rise of the wiring harness is verified through continuous high-current output to verify the stability of the wiring harness.

For more information, please visit ITECH website www.itechate.com