With the accelerated development of Mini-LED technology, ITECH high-precision power supply can still be used like this......

Guide Autonomous driving technology makes the central control display become the core interaction point of the vehicle, and the driver can almost complete all operations except vehicle driving through a single display. Since 2022, a number of cars equipped with Mini-LED screens have been released, including NIO ET7 and ES series, Cadillac LYRIQ, Ideal L9, etc. Benefiting from Chinese and American automakers, the shipment of Mini-LED displays for vehicles will be about 140,000 pieces in 2022. It is expected that Mini-LED displays will explode in the field of automotive displays in 2023, and the shipment volume is expected to reach 450,000 pieces. As Mini-LED displays have gradually matured, it is expected that more car manufacturers will adopt Mini-LED backlight displays in 2024, and the shipment volume is expected to reach nearly 1 million units.

Why Mini-LED displays are more concerned by automakers

01 Mini-LED displays can generally reach a peak brightness of more than 1000 nits, or even 2000 nits. Compared with OLED brightness, the brightness has been significantly improved. The full-screen high-brightness feature can adapt to strong light entering the car in outdoor environments such as snow and the sun. Indoor scenes to ensure driving safety;

02 Mini-LED can be automatically turned on or off according to the brightness and darkness of the screen, and the power consumption is only 70-80% of that of OLED, which meets the needs of automobile energy saving;

03 The in-vehicle displays are gradually becoming larger. Mini-LED backlights can meet the requirements of large sizes and have high-curved displays. Compared with traditional side-lit backlights, the optical performance of high-curved surfaces is better;

04 Compared with organic OLEDs, which are prone to screen burn-in risks, inorganic Mini-LEDs continue the advantages of high reliability of LEDs, and the life of components in automobiles is especially important.

*Table 1 Comparison of various display technologies*

Therefore, Mini-LED backlight displays have higher brightness, more delicate images, lower power consumption, longer life, and lower cost (lower production threshold). It is not difficult to find why Mini LED materials are the mainstream choice of current car manufacturers.

In 2022, Chinese automakers Nio and Roewe will successively use Mini-LED backlight displays as dashboards, central control displays, and audio-visual interactive panels. GM has launched a large size Mini-LED backlit display. In the automotive supply chain of Mini-LED backlight modules, domestic automakers often use panels such as BOE to form automotive display modules; European and American automakers mainly use panels from AUO and Innolux, paired with their own automotive display modules, and finally deliver them to manufacturers such as Bosch and CarUX for system integration.

Suppliers currently deploying Mini-LED backlight technology for vehicles include: BOE, Jufei Optoelectronics, Innolux, Longli Technology, Tianma Microelectronics, TCL Huaxing, Longteng Optoelectronics, Huacan Optoelectronics, Ledman Optoelectronics, Lianjian Optoelectronics, Skyworth Digital, Baoming Technology, Nationstar Optoelectronics, Vogel Optoelectronics, Yiguang Electronics, Refond Optoelectronics, Macroblock Technology, Weishi Electronics, Dongguan Guangze, Haiwei Technology, Hongli Zhihui, Jinke Electronics, Hongli Zhihui, Jingtai Co., Ltd., Sanan Optoelectronics, Qianzhao Optoelectronics, Jucan Optoelectronics, Hua Yinxin, Tiandian Optoelectronics, etc.

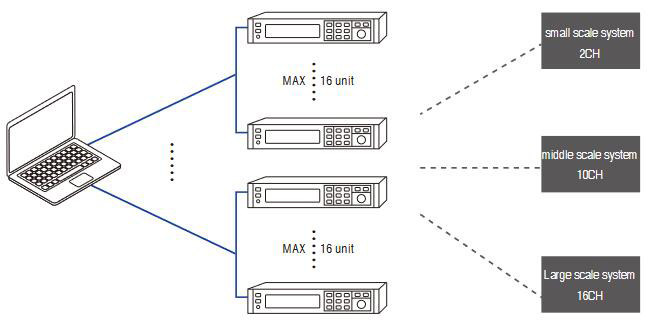

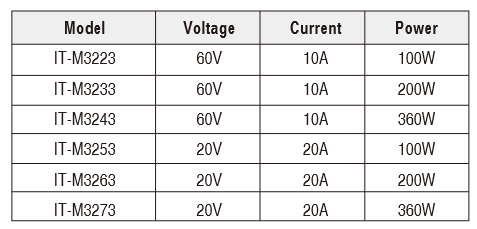

ITECH's latest IT-M3200 series high-precision programmable DC power supply has three current ranges and nA-level current resolution, which can meet users' current measurement needs from ampere level to microampere level. The volume is only 1U half-rack, but the multi-channel synchronization function is especially suitable for testing LED, OLED, and Mini LED. A single communication card can control 16 channels, up to 256 channels.

Customers of the ITECH production line are verifying that the standby current of the car Mini LED backlight screen has reached the μA level. The focus of the test is often around verifying the changes in power consumption and current under various working conditions. The IT-M3200 can not only meet the customer’s requirements for the standby current Accuracy requirements, and ultra-small size, ultra-multiple channels are especially suitable for building test systems.

Relying on more than ten years of experience in the design and development of power supplies and electronic loads, ITECH is cooperating with new energy vehicles and photovoltaic companies for win-win and two-way development. Welcome to visit ITECH official website www.itechate.com for more product information.